Michael Funk

Prosthetic Arm: Articulation

Prosthetic Arm: Articulation

SUMMARY

Summary

This project is about the development and design of a low cost prosthetic with articulation. Due to the availability of 3D printing developing a cheap and viable low cost articulated that is available to the masses. This prosthetic should be able to

-

As costs of components have lowered and more technology has become available prices of prosthetics have not come down. The ability of robotic prosthetics has stagnated in large and expensive design programs with little ability of a common person acquiring a mechanically articulating hand that can replace a hand for many daily tasks.

-

This object has to provide grip replacement of a hand for a person. This prosthetic device fingers must articulate like fingers.

Design Challenges

The prosthetic must have functionality that a standard hand has. The prosthetic has to have the movement of a finger and the ability to hold between 20 lb and 30lb. This would be tested with

-

Finger curls 270 degrees

-

Moving wrist with 90 degree angle

-

Gear motion for the wrist

-

Hold 20 lb to 30 lb worth of grip force

Identify an optimization opportunity within the project

-

Easy movement and simplified parts

-

Identify known challenges

-

Cost of miniaturized parts

-

-

List any help needed from industry

Industry Requests

-

3D printing ABS/PLA – printer availability

-

Small body Nema 17 stepper motors

ABOUT

As costs of components have lowered and more technology has become available prices of prosthetic's have not come down. The ability of robotic prosthetic's has stagnated in large and expensive design programs with little ability of a common person acquiring a mechanically articulating hand that can replace a hand for many daily tasks.

Design & Construction

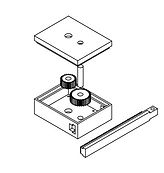

The design for this articulated hand is being developed as a replacement that is lightweight and has simple to produce parts. The tools required should only be a 3D printer and simple hand tools. The form of the hand should be functional and have a range of movement that allows the user most of the functionality of a hand.

Some of the design challenges that have presented themselves to the designers are:

-

Size requirements

-

Weight requirements

-

Strength requirements

-

Speed requirements

These design challenges have been considered and several different choices of movement were considered.

The idea is to have a modular design that anyone with time and a printer can build with parts available from online or a store. Another design choice was for ease of use.

The design also takes into consideration that people may only have limited construction knowledge and have only access to basic tools. Parts to be purchased have been sourced to be cheap and commonly available to the public.

The gearing used in the modular system is RC car gears that should be able to be purchased at any hobby shop or online. Currently they are hardened steel gears that are more expensive but with some optimization the design could use some standard non-hardened gears.

Drawings

Data

Saftey

Senior Project file

I am currently a senior at Central Washington University. My major is Mechanical Engineering. In this section you can find multiple means of contacting me.

My current plan is to seek employment in the engineering field in the production sector. The type of job I am looking for is something that challenges me and I don't have to sit at a desk all day.

Inquiries

For any inquiries, questions or commendations, please call: 425-941-8331 or fill out the following form